About Us

Freeway Bearings Corp, has been engineering, manufacturing and supplying semi-precision/precision ball bearings for over 60 years. From flanged bearings to glider bearings and everything in between; Freeway is the place for all your bearing needs. For B2B inquiries, contact us directly.

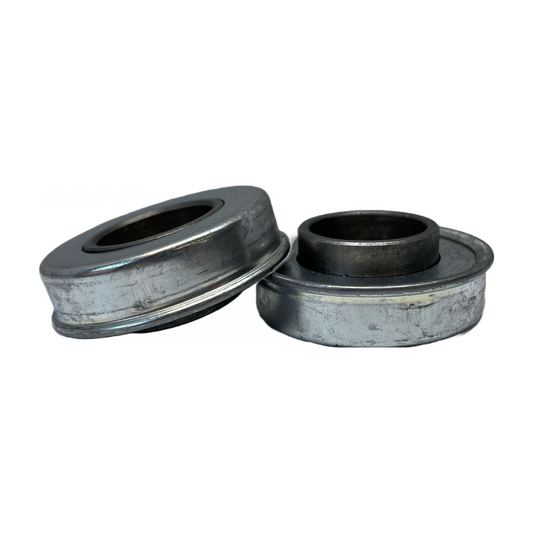

Flanged Bearings

Flanged Bearings

Freeway established the modern commercial-grade bearing design. Some of the most common...

Skateboard Bearings

Freeway Blues Abec 7 - Silver - Sold in tins of 8

Freeway Blues Abec 9 - Silver - Sold in Tins of 8

Freeway ZR Ceramic - Only $5.00 Ea. Sold in Tins of 8

FAQ

Do we ship to your country?

Yes, Freeway Bearings ships world-wide. Many shipping options are available at check-out, choose the best one that suits your needs.

Need help differentiating between products?

If you have any questions regarding our products, feel free to reach out to us. You can contact us at 905-564-2288 or by email at bearings@freewaybearings.com. Typical response time is same day or next day at the latest.

Is there a list of your bearing sizes?

Yes. Visit the ASF/PA Bearings page located in the sub-headings above or in the drop-down menu located in the top-left if you are on mobile. If you see a product that you would like to get more information about, simply click on the product # to be directed to the product page.

Do we offer direct B2B services?

The answer is yes. Our wholesale bulk pricing is very competitive across the market. If you want a direct line with us don't hesistate to reach out to us immediately. You can contact us at 905-564-2288 or by email at bearings@freewaybearings.com.

Who do we currently supply?

Freeway Bearing is currently supplying some of the largest OEM manufacturers/distributors in North America. Companies such as Genie, Chamberlain (liftmaster), Garlands, Hillman and Arrow Tru-Line are using our products.